Product Development Efficiency in the Age of Naturalness

Food Processing conducts an annual R&D Survey to better understand the primary forces and focus areas driving product development plans across the industry. For several years, the survey has opened with the same question:Which of the following will be most important for your R&D efforts this year?

“Really New” Product Development

Cost Control

Existing Product Improvement

“Cleaning Up” Current Products

Product Line Extensions

Prepare for New Nutrition Facts Panel*

In the past few years (2016-2018), three focus areas continue to remain top of mind for product developers. It’s not surprising clean label formulations and reformulations are key priorities, but what’s noteworthy is the rising emphasis on cost control, especially since 4% of respondents indicated their R&D budgets are remaining the same as the prior year.

Today’s evolving consumer preferences, combined with tight budgets and deadlines, heighten the importance of efficient product development.

Reimagining Product Development with Simple Ingredients

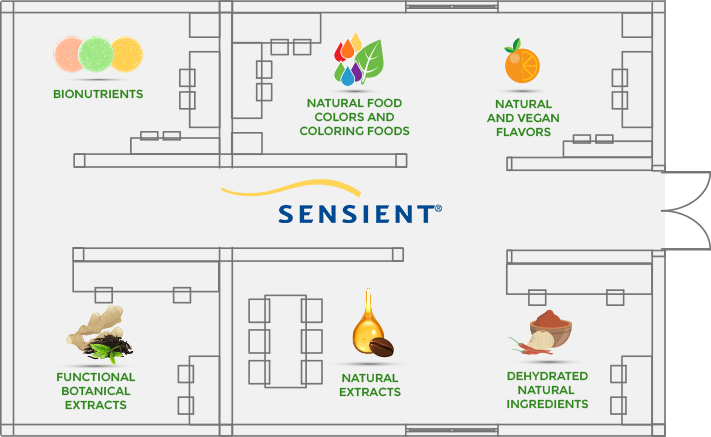

Through interaction with our customers across both Sensient Natural Ingredients, Flavors and Food Colors, we have identified three key strategies to reduce complexities when formulating with clean ingredients.

#1 Turn-Key Compatibility of Natural Ingredients

Customer Hurdle: Key project milestones were missed due to additional efforts needed in recipe formation and refinement

- Example: Unexpected natural ingredient interactions during formulation

- Example: Stability problems during pilot plant trials

Solutions to some of these problems are not always so obvious, especially when ingredient suppliers address them on the back-end of product development versus the start.

Strategy: Collaborating with suppliers in the early stages of the development process can help mitigate the chance of reformulation and product launch delays due to unforeseen interactions. For example, partnering with a supplier like Sensient who has extensive experience in managing full ingredient systems of color, flavor, extracts, and other natural ingredients helps to ensure compatibility from bench formulation to batch scale-up.

Turn-key solutions of integrated or complimentary natural ingredients can optimize product development efficacy and potentially increase speed to market. Formulating with ingredient solutions ensured for compatibility is also a proactive approach to cost, especially since time is money in new product development.

#2 Leverage Quantitative Sensory Testing from Suppliers

Customer Hurdle: Ensuring a new or reformulated product is free of defects

- Example: Unwanted flavor profiles from certain colors from natural sources

Customer Hurdle: Validating a change of ingredients in a reformulation is accepted by consumers

- Example: Reducing sugar by 30% with a sweetness solution that yields the same sweet taste perception and mouthfeel as a full sugar version

Strategy: As consumers continue to define product acceptability, food manufacturers are increasingly relying on data-driven information to confirm overall liking. Quantifiable sensory information can help brands achieve a competitive advantage to reduce performance risk in the marketplace. For example, Sensient’s global sensory network can connect product formulations to sensory characteristics.

Understanding the relationship between the two enables our application technologists to enhance and refine ingredient solutions to meet consumer preferences, potential requirements, potential retailer requirements, and cost targets. For small to mid-tier size companies, leveraging the sensory capabilities of partner ingredient suppliers can be a huge cost savings, especially since it’s a service often outsourced for a high price.

#3 Share Ingredient Sourcing Values: Global Mindfulness

Customer Hurdle: Sourcing simple ingredients that positively impact society

- Example: Botanical color from a farm that built a clean water well for its developing community

- Example: Vegetable powders from crops grown in fields that promote the health of pollinators like bees, butterflies, and beetles

- Example: Natural extracts from fruits nurtured by a women business enterprise in an emerging market area

Strategy: Today, a food brand’s environmental and social responsibility, as well as a transparent supply chain, can bolster product success.

Consumers are demonstrating cultural and ideological values through their purchasing behavior. As this type of buying model becomes more common, companies have the opportunity to redefine their brand/consumer relationship through authentic ingredient stories.

But in order for brands to provide quality information about the ingredients in their products, suppliers must be more transparent about their supply chain. Opening up the doors of major initiatives like Sensient’s seed-to-shelf and agronomy program is just one example of how suppliers can increase their visibility with food manufacturers. Others may include sharing ingredient provenances, reporting food safety standards, or publishing social responsibility efforts, etc. For a better tomorrow, food manufacturers and ingredients suppliers must unite in their global mindfulness by sharing values and global beneficiaries.

Re-Imagining the Manufacturer and Ingredient Supplier Relationship

Product development is at a crossroads. Consumer preferences are progressing, information on products is more accessible, there are fundamental conversions to simple ingredients, and tin labeling and nutrition facts are coming. The food industry is evolving rapidly, and product development must evolve too. It is a pivotal time to rethink R&D and formulation practices for brands repositioning themselves to address the market realities in today’s age of naturalness.

Discover what we can create together as a comprehensive supplier of natural ingredients.

Leverage Sensient as your innovation partner and ethical steward to solve your natural product development problems. We are here for you.