Understanding Cost-in-Use versus cost per kilogram

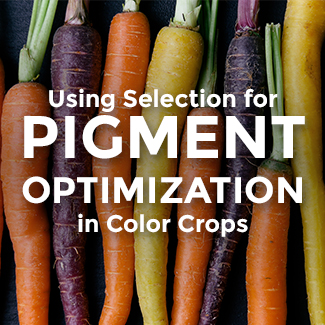

The cost of natural colors in a final product formulation is greatly impacted by usage rates. Thus, cost-in-use is the decisive measure to take a close look at, not merely the absolute cost per kg. The potential variation in pigment concentration and color development in a given application amongst vegetables used for color solutions, one example being carrots, greatly impacts cost-in-use. Carrots are part of people’s diet in many regions of the world. Orange carrots get their characteristic bright yellow-orange color from carotenoids. For many consumers it is intuitive that carrot juice is yellow-orange in color, whilst carrot juice concentrate has a more intensive color shade caused by a higher pigment concentration; due to its concentrated form, it is sold at a higher price per litre. Orange carrots are part of the Daucus carota species and provide an excellent color source for food coloring. For example, special grade carrots can be coloring foods for the industry. Alternatively, they can be utilized for color extraction. In both cases, the carrots differ from the ‘average supermarket carrot’ and contain at least double or triple the amount of pigments. Consequently, they come at a higher cost, yet they provide unique coloring properties. In order to optimize the color pigment yield, it is key to select the right carrot grades that best provide those properties desired.

A key factor that contributes to the cost of natural colors in a final product formulation is the usage rate. Thus, the most effective approach to run cost analysis of two or more solutions is cost-in-use comparison versus looking at the cost-per-kilogram. The potential variation in pigment concentration amongst vegetables and fruits used for color solutions greatly impacts cost-in-use. To take the carrot example above, a drop of standard carrot juice in water colors less than a drop of carrot juice concentrate does in the same amount of liquid. This simple example of “a little going a long way” demonstrates that the absolute product cost should only be reviewed in combination with the respective usage or dosage rate, in particular when comparing it to another product.

Orange carrots are part of the Daucus carota species and provide an excellent color source for food coloring. For example, special grade carrots can be coloring foods for the industry. Alternatively, they can be utilized for color extraction. In both cases, the carrots differ from the ‘average supermarket carrot’ and contain at least double or triple the amount of pigments. Consequently, they come at a higher cost, yet they provide unique coloring properties. In order to optimize the color pigment yield, it is key to select the right carrot grades that best provide those properties desired.

A key factor that contributes to the cost of natural colors in a final product formulation is the usage rate. Thus, the most effective approach to run cost analysis of two or more solutions is cost-in-use comparison versus looking at the cost-per-kilogram. The potential variation in pigment concentration amongst vegetables and fruits used for color solutions greatly impacts cost-in-use. To take the carrot example above, a drop of standard carrot juice in water colors less than a drop of carrot juice concentrate does in the same amount of liquid. This simple example of “a little going a long way” demonstrates that the absolute product cost should only be reviewed in combination with the respective usage or dosage rate, in particular when comparing it to another product.

Another example, for instance, is a product developer testing two different black carrot color solutions, which differ in pigment concentration. The solution from the more concentrated variety typically equates to a lower usage level and might have a much lower impact on total formulation cost.

Another example, for instance, is a product developer testing two different black carrot color solutions, which differ in pigment concentration. The solution from the more concentrated variety typically equates to a lower usage level and might have a much lower impact on total formulation cost.

While the cost per kilogram could seem high, you really need to calculate the cost-in-use to know which color is the most economic.

Sensient’s agronomy team is working on our natural colors with the same principle: more for less, and we are making great strides in developing botanical sources with higher pigment levels. Watch this video to learn more:

Are you interested in trialling our portfolio of concentrated coloring foods or natural colors?