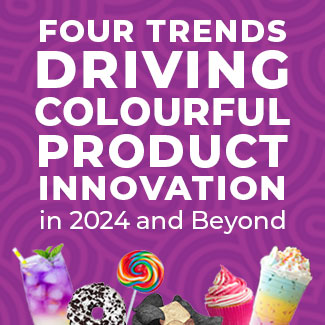

Emulsion Stability in RTD Sparkling Beverages

The Value of Color in Beverages

While the word “taste” refers to what is detected by our taste buds, consumers’ perception of taste goes much further than that. Tasting a beverage is a multi-sensory experience constructed from a number of things including our palate, along with the beverage’s visual appearance, aroma, and mouthfeel. Our brains use all of our senses to interpret the beverage and arrive at the decision of our overall liking.

In beverages, color plays a prominent role in establishing a consumer’s flavor expectation prior to tasting. The color must match the consumers’ frame of reference for its respective flavor. For example, one would probably expect a sparkling strawberry beverage to be a matching berry color shade or a mango-flavored juice to be bold orange. Understanding consumer perspective is very important, especially since more than any other attribute, taste expectation (which can be impacted by color) drives consumer liking. Our research indicates brighter colors are preferred in beverages because of their association to a better and sweeter taste.

The Complexities and Necessities of Beverage Emulsions

With the growing popularity of sparkling beverages, we are seeing a wave of interest in natural color emulsions. Any colors from the carotenoid family like beta-carotenes, paprika, or turmeric require emulsification to function in water-based systems like a sparkling beverage base. Inherently, carotenoids are oil-soluble, however emulsions enable them to become water-soluble or –dispersible. Sensient’s Advanced Emulsion Technology (AET™) and equipment innovatively decrease the particle size of the oil-soluble colors and transforms them into a stable water-soluble or water-dispersible solution.

Sensient Colors

High Stability < 50 nm

Industry Standard

Low Stability > 200+ nm

Although complex, emulsions significantly add value to many popular beverage concepts, and are able to drive flavor expectations. Given the correlation of color and taste on purchase intent, developers should certainly not sacrifice on color performance in the formulation. They enable developers to achieve natural color shades that were previously unattainable, yet formulating with them requires some experience.

One of the biggest challenges for beverage developers is maintaining the emulsion’s stability. The results of a broken emulsion can be pretty undesirable including color agglomeration, cap staining, and/or color ringing.

SEDIMENTATION

CAPSTAINING

Since many of the ingredients in a beverage system could potentially be emulsions or contain emulsifiers with the exception of water and most sweeteners, there is a high possibility for ingredient interaction. Given our teams’ experience developing with emulsions, we would like to share some insights on how to enhance equilibrium.

Step 7: Citric Acid

Step 6: Cloud Emulsion

Step 5: Juice

Step 4: Color Emulsion

Step 3: Flavor Emulsion

Step 2: Sweetener(s)

Step 1: Water

INSIGHT: ADDING INGREDIENTS AFTER THE COLOR EMULSION

What can happen?

Multiple emulsions in a beverage system increases the chance for undesirable reactions or incompatibility between ingredients, potentially resulting in a coalescence.

Color Advice:

One way to mitigate this risk is through order of addition, by adding the color emulsion last, which can reduce the potential for unintended interactions.

Color ringing as a result of broken emulsions

INSIGHT: DEVELOPING WITH INCOMPATIBLE FORTIFIED INGREDIENTS

Example: Like colors sourced from carotenoids, ingredients used for fortification, such as some vitamins , are innately oil-soluble and require emulsification of their oil particle in order to be fully incorporated into a water-based system, like a sparkling beverage.

What can happen?

Sometimes the emulsifier used to make a vitamin for fortification is not compatible with another emulsion in the beverage system, such as the flavor or color. If incompatibility is the case, all of the systems’ emulsions are highly susceptible to breaking. As one emulsion breaks, it can create multiple interactions and disruptions in the beverage formula.

Color Advice

While trial and error testing is one way of working through incompatibility issues, the most efficient way would be teaming up with an experienced color partner with knowledge in ingredient compatibility. Sensient’s longstanding history as both a color and flavor supplier has provided us with a vast collection of ingredient compatibility data at our fingertips. Our application team uses this evolving data in their research projects to continuously optimize formulations.

INSIGHT: FORMULATING FLAVOR, CLOUD AND COLOR SEPARATELY

Example:

Developing a mango flavor emulsion independently from the yellow beta-carotene color emulsion

Beta–Carotene Color Emulsion

Cloud Emulsion

Mango Flavor Emulsion

What can happen?

The emulsifiers in the flavor emulsion may not be compatible with those used in the color emulsion, resulting in adverse interactions and results.

Color Advice:

Partner with a supplier who is able to manage systems together (color, flavor, and cloud).

At Sensient Colors, we leverage the expertise of our sister company, Sensient Flavors, as well as our collaborations with other flavor houses to create integrated solutions such as:

- Combining color and flavor emulsions into one compatible system

- Ensuring the separate emulsions are compatible by formulating with the flavor house and the beverage manufacturer

- Using our Smooth Cloudy Emulsions technology to offer a combined solution of color and cloud in a range of shades