Understanding Cost-In-Use versus Cost per Pound

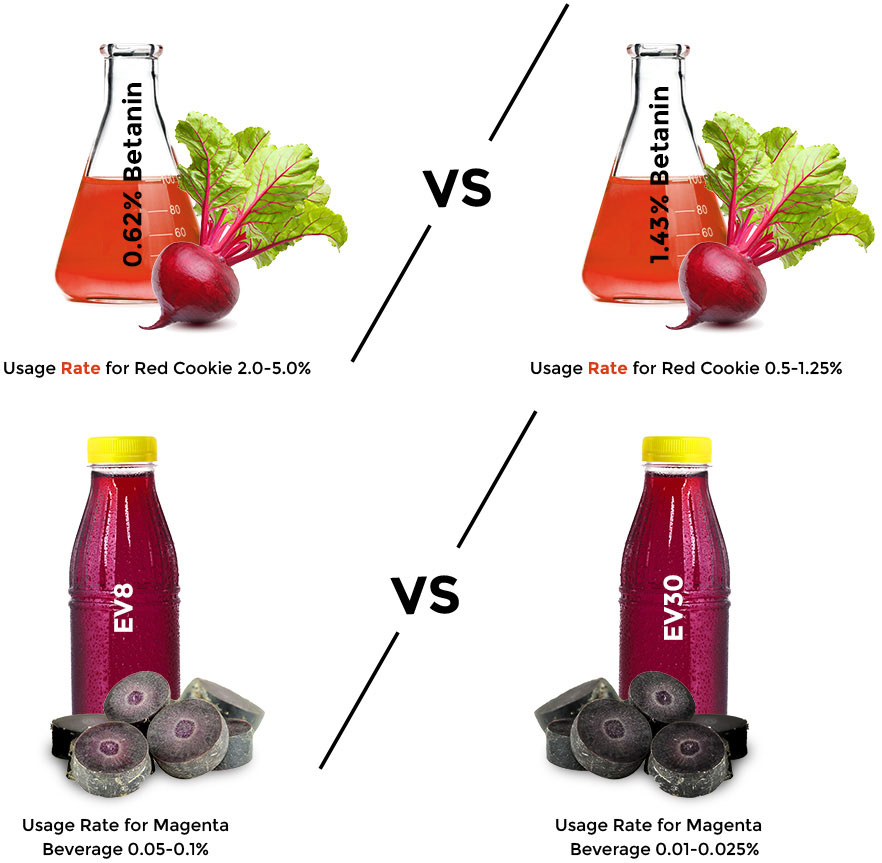

A key factor that contributes to the cost of natural colors in a final product formulation is the usage rate. Thus, the most effective approach to cost analysis of two or more solutions would be cost-in-use comparisons, versus cost/lb. The potential variation in pigment concentration amongst botanicals used for color solutions greatly impacts cost-in-use.

For example, a product developer might be trialing black carrot color solutions from two different suppliers whose black carrot sources vary in pigment concentration. The solution from the more concentrated botanical typically equates to a lower usage level and might have a much lower impact on total formulation cost.

While the cost per pound could seem high, you really need to calculate the cost-in-use to know which color is most efficient.

Concentration is not specific to the color industry, there are many other fields that focus on higher strength products, including:

The message of concentrated products is generally similar, “a little goes a long way,” and this result is exactly what Sensient’s agronomy team is working on with our botanicals for color—natural color, more for less.

Watch this video to learn more:

Sensient is making great strides in developing botanical sources with higher pigment levels. Our efforts will continue to improve over time.

Interested in trialing our new portfolio of highly concentrated natural food colors?