The Physics of White

White colour in the food industry

White colour in the food industry is obtained in three different ways:

Incorporation of Air

Crystallisation of e.g. sugar, polyols or fats

Incorporation of white food pigments

Beating an egg white transforms a transparent viscous liquid into a white mass. The same effect is used in the production of marshmallows, when air is incorporated into a sweetened gelatine-containing mass. The physical reason for this phenomenon is the formation of small pockets of air within the mass, causing the formation of small ‘particles’ with a difference in refractive index, air against sugar and gelatine, at which interface the white light is refracted and scattered.

The second option to whiten a product is to use sugars and polyols. When applying those to the surface of products in thin layers, they have a tendency to produce small crystals which refract and scatter light. Soft and hard coated confectionary products take advantage of this phenomenon.

The third option of whitening a food product is the incorporation of a whitening pigment. Calcium carbonate (INS 170) as whitening additive is allowed in Europe and in most parts of the world. The two products differ in their chemical stability and whitening power. The reflectance of titanium dioxide is about 3 times higher than that of calcium carbonate against an air interface when used in, e.g. coated confectionary, and about 10 times higher in a low dry substance aqueous environment, e.g. salad dressing.

Whitening solutions with Sensient

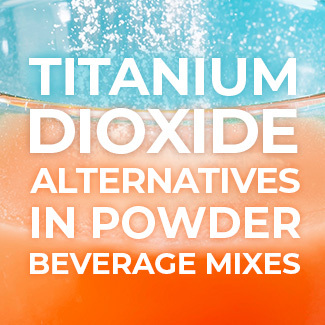

Both whitening additives, namely INS 170 and INS 171, face several challenges. Titanium dioxide is under pressure and calcium carbonate is instable in acidic environments. Due to this, it is not urprising that some product developers are seeking alternative solutions to whiten or opacify their respective products.

In order to cater to this need and address these challenges, Sensient has developed the global Avalanche platform. The innovative Avalanche portfolio is a range of alternatives to Titanium Dioxide and offers strong whitening or opacifying effects. The products are designed to offer solutions for most regions in the world in a large variety of applications including confectionery, instant drinks, sauces and pet food.

Complementing existing solutions with whitening effects in panning, we are now expanding the product range and introduce ingredient systems that can be both starch- or mineral-based and that remain heat, light and pH stable leading to the desired shades of white. The dedicated food technologists in our Application Service Centre will assist to solve any questions or challenges that you may have in mind to find the best suitable match. For those interested in learning more about using Avalanche, please do not hesitate to request a consult, or request a sample, if you are ready to begin trial work.

1The effect caused by the difference in refractive index was described by Augustin Jean Fresnel, the combined particle size and refractive index effect by Gustav Mie.