Natural Colour Emulsion Stability in Beverages

Today, health-conscious consumers are searching for beverages with natural flavours derived from plants and fruits and fewer artificial additives and overly processed ingredients.

Currently natural fruity flavours are a top choice for many consumers such as orange-blueberry-infused sparkling water, peach and orange blossom infused water, or a blend of pineapple and lemon in a craft soda. Brands can explore many options like grapefruit and rosemary, pomegranate-mint and passionfruit-guava to build some indulgent and exciting flavour experiences for consumers.

Exploring the Latest Healthy CSD Beverage Trends- Report BevSource 2023

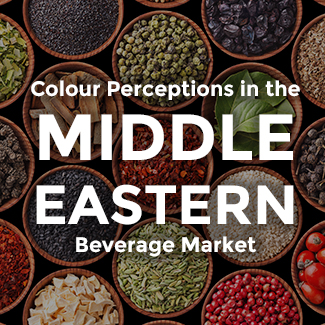

Of course, consumer’s perception of taste goes much further than the sensation of flavour perceived in the mouth.

For consumers all around the world, tasting a beverage is a multi-sensory experience combined with visual experience, aroma and mouthfeel. When it comes to creating the visual experience part, colour plays a prominent role in establishing a consumer’s flavour expectation prior to tasting. The colour must match the consumers’ frame of reference for its respective flavour. Our research indicates brighter colours are preferred in beverages because of their association to a better and sweeter taste.

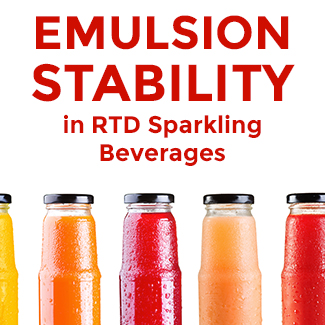

The Challenge and Advantage of Emulsions in Beverage

It is crucial for product developers to understand the role of emulsions in achieving vibrant and enduring colours and the factors that affect colour stability.

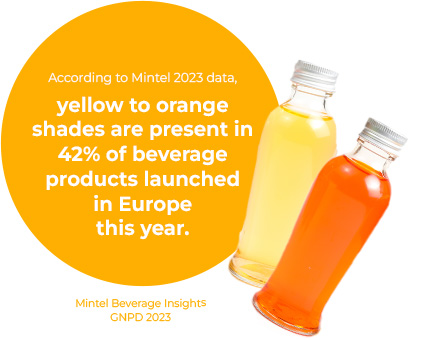

Emulsions significantly add value to many popular beverage concepts and are able to drive flavour expectations. Latest launches in beverage segment show that brighter colours are preferred in beverages because of their association to a better and sweeter taste and there is a growing interest of using natural colour emulsions in sparkling beverages to achieve bold shades of oranges, red and pinks.

In general, “Carotenoid” family of colours are highly preferred to achieve yellow to orange shades.

However, any colours from the carotenoid family like beta-carotenes, paprika require emulsification to function in water-based systems. Inherently, carotenoids are oil-soluble, however emulsions enable them to become water-soluble or –dispersible.

Emulsification may be the solution but there is a big challenge for beverage developers, which is maintaining the emulsion’s stability in this case.

Formulation defines the characteristics of the emulsions. There are few factors to consider establishing a stable emulsion such as:

- Different pH levels can affect the stability. Some emulsifiers are unstable in low pH levels. Understanding the optimal pH range for your specific colour emulsion can help you achieve the desired colour stability in your beverages.

- High shear and alcohol levels can also cause breaking in the process and result in unstable emulsions

- Combining formulations that contains the same emulsifiers also plays an important role in emulsion stability.

- Particle size and distribution also has an impact on colour turbidity and appearance in the final product.

The results of a broken emulsion can be undesirable including colour agglomeration, cap staining, and/or colour ringing. Discover our insights and colour advice about emulsion stability in beverages in more detail here.

How to overcome challenges with:

Sensient’s Advanced Emulsion Technology (AET™) and equipment innovatively decrease the particle size of the oil-soluble colours and transforms them into a stable water-soluble or water-dispersible solution. This technology is oil-in water emulsions of carotenoids such as beta carotene or paprika extract. Sensient’s AET™ can offer you superior colour efficiency and excellent oxidation stability.

Beta-carotene solutions offering a wide range of orange hues to developers for beverage applications. These colours are preferred for their excellent stability and wide colour variety, from warm peachy oranges to yellow-orange shades. Beta-carotenes are also available in the red and yellow family for even more options.

Natural carotene, equally producing shades from yellow to orange-reds in beverage applications, is nutritionally valuable as a vitamin A precursor and antioxidant. It provides a great opportunity for developers to formulate with natural colouring solutions.

Paprika is a heat-stable solution well-recognized by consumers on an ingredient list. Naturally oil-soluble, it requires expertise to create solutions to perform well in water-based systems. With Sensient’s emulsification technology it becomes a perfect fit for beverage applications. We also know how important food safety is to our customers. Our Certasure™ program protects our paprika solutions from risks like pesticides so that brands can be confident in the food safety standards of their colour ingredients.

Pure-S™ Paprika combines the benefit of great colour performance, excellent stability and a clean taste. Thanks to a gentle purification technology off-notes in beverage applications are reduces or eliminated. As a spice, paprika is both boldly coloured and boldly flavoured in its natural state, so the Pure-S™ technology is used to ensure that develope rs can leverage the rich orange hues without a flavour impact.

Lutein is part of the carotenoid family occurring in green plants and petals of various flowers. On packaging labels found as E161b, it provides a range of warm yellow to orange shades for transparent, semi-transparent or turbid beverages.

AET: Sensient’s Advanced Emulsion Technology (AET™) offers developers both clear and cloudy solutions with excellent stability, so that developers do not have to worry about colour agglomeration, cap staining or ringing.