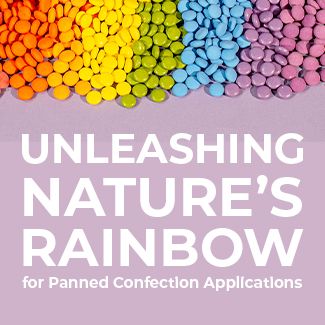

Beet Juice Colour Solutions for Diverse Development Needs

Increasing Demand for Beet Juice Colour Solutions

As consumer demands for transparency and clean label ingredients continue to rise year-over-year, food colour solutions, like beet, that can be labeled as beet juice or vegetable juice rise even further in popularity.

Brands with clean label goals often look for “recognizable” ingredients that consumers will easily understand and potentially perceive as “better-for-you”, as they convert from synthetic ingredients or formulate anew with all-natural ingredients including natural colours.

Colour from beet juice is widely used in the market because it’s cost-effective and globally sourced. Because of its demand in the market, Sensient has been working on establishing the most extensive portfolio of beet juice colour solutions and technologies to cater to the growing and diverse needs of product developers.

Most Diverse Beet Juice

Colour Portfolio

A cost-effective, straightforward natural colour that shines in applications with a neutral pH range and where intense heat is not applied and plating characteristics are not needed.

MAGNA RUBY

Sensient’s Magna Ruby colour solutions are designed from more purified beets, enabling better performance in high heat conditions.

SUPRARED™

SupraRed™ solutions are made from highly concentrated and purified beets, designed to withstand the harshest heat temperatures, including extrusion.

A beautiful bright red shade, our beet-based Microfine™ solution is a dry powder that is extremely successful in seasonings and other powdered applications.

Beet Microfine™ can also be dispersed in a liquid matrix, which may be preferred over a powder solution based on customers’ needs and processing parameters.

Considerations When Price Shopping for Beet Juice Colours

When calculating spend on natural colours, it’s important not to jump to conclusions based on cost per pound or kilogram, because cost-in-use (how much of the colour solution is needed in the finished good) is what reveals overall cost efficiencies to buyers and purchasing managers.

“Cost-in-use” more accurately reflects the actual final cost of colour in the formulation.

Colour solutions like SupraRed™, for example, that are made from highly concentrated raw materials most often lower the usage rate needed to achieve the desirable shade target—the saying less is more rings true here.

Sensient is continuously trying to lower cost-in-use for our customers across our entire portfolio. Our global agronomy and R&D teams are working on opportunities to increase cost efficiency with new sourcing and technologies.

If you are interested in trialing one of the beet solutions outlined above, start a sample request form.