Super-Natural Heat Stability from a Vegetable Juice

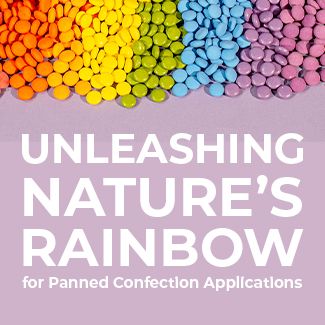

Several years ago, Starbucks came under fire for using carmine in some of their beverage and red velvet baked goods. Despite its status as a non-certified or natural colour, many of their customers found the use of ‘bug juice’ a turnoff. The company then announced their transition away from the colour. Of course, carmine is also not Kosher or Halal, so its use in food and beverage products had some drawbacks anyway. Why is this so relevant today? As most of you know, a wave of consumer packaged food companies and retailers have recently announced their intention to convert from certified synthetic colours to those from natural sources. The list includes Mars, Mondelez, Kellogg, Aldi, and General Mills. Advances in natural colour performance relative to artificial colours have been impressive. However, until now, some major gaps existed in the natural colour technology landscape. A truly heat stable natural red from botanical sources for baked goods and dry grocery products was among the biggest missing technologies.

The pH Problem

Baked goods and many dry grocery products typically are in the 5-7 pH range. During baking or heat processing production, the pH can rise even further. While nature provides us with several red anthocyanin options, these sources will shift from red to purple under these pH conditions.

The Maillard Reaction

French scientist Louis-Camille Maillard first explained what happens when amino acids react with sugar at elevated temperatures about a century ago. Beet is a logical alternative to anthocyanin colours in a neutral pH environment. Alas, because of the Maillard effect, beet browns during the baking or heat step of manufacturing. This issue can also arise during high shear mixing or extrusion, particularly in cereal or pet food applications.

Advances in natural colour performance relative to artificial colours have been impressive. However, until now, some major gaps existed in the natural colour technology landscape. A truly heat stable natural red from botanical sources for baked goods and dry grocery products was among the biggest missing technologies.

The pH Problem

Baked goods and many dry grocery products typically are in the 5-7 pH range. During baking or heat processing production, the pH can rise even further. While nature provides us with several red anthocyanin options, these sources will shift from red to purple under these pH conditions.

The Maillard Reaction

French scientist Louis-Camille Maillard first explained what happens when amino acids react with sugar at elevated temperatures about a century ago. Beet is a logical alternative to anthocyanin colours in a neutral pH environment. Alas, because of the Maillard effect, beet browns during the baking or heat step of manufacturing. This issue can also arise during high shear mixing or extrusion, particularly in cereal or pet food applications.

Off-Notes and Texture Problems

Because of the much higher usage rates typically required for natural colours from beet and other vegetable juices, off-notes can be another issue. Additionally, in many baked and packaged food applications, the high usage rate will impact texture. This effect usually means less rise than desired in the final product and crumbling in some applications.

Because of the Starbucks story and growing consumer demand for natural colour sources, we began working on a solution to the heat stable red challenge. After several years of hard work, we finally have a solution — a natural vegetable juice that delivers bold, vibrant red shades that withstand heat in a neutral pH environment. We call it SupraRed™ and it provides a number of key advantages, including the following:

Off-Notes and Texture Problems

Because of the much higher usage rates typically required for natural colours from beet and other vegetable juices, off-notes can be another issue. Additionally, in many baked and packaged food applications, the high usage rate will impact texture. This effect usually means less rise than desired in the final product and crumbling in some applications.

Because of the Starbucks story and growing consumer demand for natural colour sources, we began working on a solution to the heat stable red challenge. After several years of hard work, we finally have a solution — a natural vegetable juice that delivers bold, vibrant red shades that withstand heat in a neutral pH environment. We call it SupraRed™ and it provides a number of key advantages, including the following:

- Unprecedented heat stability

- Clean and simple ingredient labeling

- Low usage rates

- Kosher and Halal

- Broad range of shades possible in combination with other natural colours