Sugar Reduction Strategies for Frosted and Coated Cereal

“In a category known for its high sugar content, sugar reduction will be a key reformulation in cereals. @SensientColorAP”

Challenging Effects of Sugar Reduction in Cereals

#1

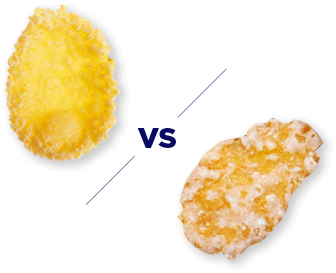

LOSS OF FROSTED LOOK

Removing sugar content from cereal will impact its frosted appearance. Some brands would simply correct this loss by using titanium dioxide in place of sugar to enhance the white crystallized appearance. While this might seem like an easy fix, titanium dioxide brings additional challenges. Since TiO2 is an insoluble pigment, difficulties can arise when it comes to cleaning the coating reel of the manufacturing process. Furthermore, titanium dioxide has been under continuous scrutiny from advocacy groups and regulatory bodies. It’s also unfamiliar to many consumers and would generally not be perceived as a “clean ingredient” option.

A novel solution to these issues would be Sensient’s Avalanche, in particular the new, water-soluble Avalanche™ Xtra for improved opacity and whiteness of coating. The solubility function provides clean-in-place (CIP) processing for your coating reels and any additional equipment encountered. Although Avalanche™ Xtra is water-soluble, it adds opacity to the coating syrup, so it’s recommended to add it late in the process to minimize exposure time to heat and water. The Avalanche Xtra colour system can be labeled as either Vegetable Juice or Spirulina Extract depending on the version.

#2

CHANGES IN CEREAL PIECE TEXTURE

Sugar coating typically extends the bowl life of cereal, so with reductions, the texture of cereal pieces after milk is added could be greatly affected.

To prolong the life and frosted appearance of cereal pieces that have undergone a sugar reduction, coating systems like Avalanche™ Xtra can be added to the coating syrup to optimize the adhesion of each cereal piece, extending bowl life, texture and appearance.

#3

UNDESIRABLE AND DIFFERENT FLAVOUR

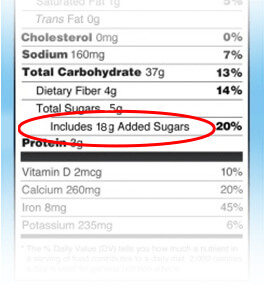

Reducing sugar might drastically change a cereal’s familiar sweet profile for its consumers. While this might be in favour for some consumers, most want the best of both worlds—a great taste but less sugar.

To correct visual and textural challenges due to sugar reduction, you could use a titanium-free coating system. Then, maintain sweetness by using a sugar-free sweetener system combined with a taste modulation technology to boost the sweet taste & mouthfeel without adding any sugar or calories. While the price of sugar-free sweetener systems has traditionally been high, the prices for high fructose corn syrup (HFCS) are rising due to a wet growing season, so the price gap between high calorie HFCS and zero calorie sweetener systems is starting to close.

Thankfully, there are integrated coating and flavour systems available to combat all of your challenges if reducing sugar in coated or frosted cereal is on the horizon. If you would like to discuss a potential project, we welcome any conversations you might have, and our application specialists are available to assist you with any challenges.

Continue to follow our blogs as we have an exciting high-water activity addition to our line of Avalanche products coming very soon!