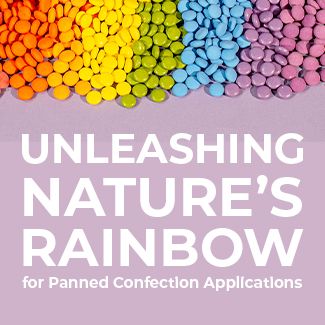

Natural Colour Opportunity in Extruded Confections

Research indicates 88% of consumers would be more likely to buy confection brands that have removed artificial colours. @SensientColor

AP

Needless to say, consumers want fewer artificial ingredients in confections. Some confectionery companies are catering to these consumer requests; for example, a Nestle press release stated “We know that candy consumers are interested in broader food trends around fewer artificial ingredients.” Shortly after this release was issued, Nestle committed to removing artificial flavours and colours in their chocolate confections. Although never officially committing to removing artificial colours in sugar confections like SweeTarts, Nestle has continuously made changes in this application area too. Then in 2015, Mars announced their intent to go even further and remove artificial flavours and colours from all confection and gum products. Today’s consumers are expecting brands to remove artificial ingredients even when they are indulging in sweet treats like confections.

The liquorice sub-category of confections is particularly interesting in the Asia Pacific market, as it is a small segment with vast opportunity for innovation in ingredients and form. However, there are some brands out there using bright natural colours to appeal to these changing consumer requests. While new room for this niche novelty exists, the doors are open for any extruded confection brands looking to naturally colour their products. In the U.S., there is actually a direct correlation between liquorice brands using natural colours and positive growth in revenue sales.

Needless to say, consumers want fewer artificial ingredients in confections. Some confectionery companies are catering to these consumer requests; for example, a Nestle press release stated “We know that candy consumers are interested in broader food trends around fewer artificial ingredients.” Shortly after this release was issued, Nestle committed to removing artificial flavours and colours in their chocolate confections. Although never officially committing to removing artificial colours in sugar confections like SweeTarts, Nestle has continuously made changes in this application area too. Then in 2015, Mars announced their intent to go even further and remove artificial flavours and colours from all confection and gum products. Today’s consumers are expecting brands to remove artificial ingredients even when they are indulging in sweet treats like confections.

The liquorice sub-category of confections is particularly interesting in the Asia Pacific market, as it is a small segment with vast opportunity for innovation in ingredients and form. However, there are some brands out there using bright natural colours to appeal to these changing consumer requests. While new room for this niche novelty exists, the doors are open for any extruded confection brands looking to naturally colour their products. In the U.S., there is actually a direct correlation between liquorice brands using natural colours and positive growth in revenue sales.

Chewy Ropes of Colour

…Consumers prefer the bold and vibrant colours of nature.

Natural Colour Opportunity in liquorice and Extruded Confection Applications

Natural colour for extruded applications is available in both dry powder and liquid forms. Achieving bright natural shades is very dependent on a manufacturer’s processing system, specifically the point of colour delivery. Let’s take a look at the three different ways:1. DRY RECIPE DELIVERY

Form: Natural Colour Powder

Advantages:

- More efficient material, shipping, and handling

- Refrigeration not required

Disadvantages:

- Intensity of shade can fade due to prolonged heat exposure during extrusion

- Typically, higher cost-in-use to achieve bright target shades

- Some opacifying agents can turn yellowish due to heat exposure

2. ZONE INGREDIENT DELIVERY

Form: Natural Colour Powder or Liquids

Advantages:

- Brighter shades due to less heat exposure

- Lower Cost-in-Use to achieve target shades

- Reduced issues with yellowing of opacifying agents

Disadvantages:

- Special care required for material, shipping, and handling

- Some liquid colours may require refrigeration

3. SLURRY INGREDIENT MIX FOR OPEN KETTLE COOK (Steam or Oil)

Form: Natural Colour Powder or Liquids

Advantages:

- In smaller batch methods of cooking where heat is controlled continuously, brighter, more intense shades are possible when colour is added later in the cook

- Refrigerated storage not required for powders

Disadvantages:

- If colour is added before the 2-3 hours’ cook time, shade degradation is possible

- Special care required for material, shipping, and handling of liquids

- Some liquid colours may require refrigeration

Source: Wenger Manufacturing, Inc., Groen Process Equipment (GPE)

Opacifying Agent:

Titanium Dioxide

- suitable for any processing

- intensifies end shade result

- scrutinized by advocacy and consumer groups in the past couple years for possible links to cancer but no supporting scientific evidence for problems in humans yet

- simple ingredient alternative to Titanium Dioxide

- ideal for Zone Ingredient Delivery

- intensifies end shade result

Reds:

Pure-S Red

Pure-S Red

- vegetable juice technology that removes unwanted off-notes inherited from the colour source

- ideal for Zone Ingredient Delivery

- label-friendly

- heat-stable vegetable juice

- ideal for high heat or continuous heat cooking like Dry Mix Delivery and Open Kettle Cook

- label-friendly

- suitable for any manufacturing style

ORANGES:

Beta Carotene

- suitable for any manufacturing style

- label-friendly

- achieve target shade more precisely

- label-friendly

- suitable for any manufacturing style

YELLOWS:

Turmeric

- suitable for any manufacturing style

- issues with light stability

- label-friendly

- heat-stable vegetable juice

- ideal for high heat or continuous heat cooking like Dry Mix Delivery and Open Kettle Cook

- label-friendly

- suitable for any manufacturing style

- greater opacity

BLUES:

Spirulina

- ideal for Zone Ingredient Delivery

- suitable for any manufacturing style

- pH environment 3.5-7

GREENS:

Spirulina + Turmeric/Beta Carotene

- ideal for Zone Ingredient Delivery

- label-friendly

- suitable for any manufacturing style

- label-friendly

- suitable for any manufacturing style

PURPLES:

Natural Reds + Natural Blues

- Pure-S Red + Spirulina/Natural Blue for Zone Ingredient Delivery

- SupraRed + Natural Blue for high heat or continuous heat cooking like Dry Mix Delivery and Open Kettle Cook

- label-friendly

BROWNS/ BLACKS:

- suitable for any manufacturing style

- label-friendly

- low usages for Brown shades

- higher usage rates for Black shades

- manufacturing based on component properties

- label-friendly

- suitable for any manufacturing style

- deepen shade by adding natural reds and blues into one single delivery solution

In 2016, 66% of all new food and drink launches in Asia Pacific used natural colours. @SensientColorAP

The extruded confection category signifies boundless opportunity to differentiate your chewy ropes or candies with natural colour.

Contact us down below to start discussing your confectionary project—we love to talk colour!