Natural Color Solutions for Yogurt & Compound Coatings

Snacking is increasingly viewed by many in the food industry as a key platform of growth. The “junk food tax” on the Mexican snack food industry hit food manufacturers pretty hard, but it also gave them the opportunity to reformulate and provide consumers with healthier offerings that fit the new calorie guidelines of 275 calories per 100g serving. More recent findings show that millennials are the most likely to snack and are increasingly seeking options they perceive as being “healthier” — including products with added protein and vitamins as well as snacks without artificial ingredients.

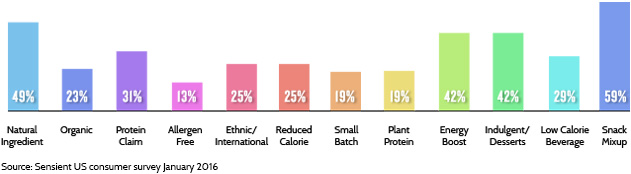

According to a consumer survey Sensient Colors conducted in January, “snack mix-ups” that combine popcorn, nuts, and other ingredients was the top idea for new food products. “Made with natural ingredients” was number two.

These are some interesting results! But they aren’t that surprising. Ready-to-eat popcorn has been one of the fastest growing categories over the past few years. Some brands are already starting to combine popcorn with nuts or other ingredients in order to add a protein element.

At Sensient, we are seeing a growing interest in adding sweetness to salty snacks. And increasingly, a variety of colors is used to differentiate from other brands or indicate a fruit flavor. Snack bar brands are also looking to add color via drizzle or compound coating. Lastly, many brands are now looking to convert their baking chips and morsels to natural colors.

Whether the application is based on a yogurt or a more traditional compound coating, formulating with natural colors is a more complex endeavor than using synthetic solutions.

Natural Color Challenge

In the case of synthetics, the obvious choice is a lake dispersion. In the case of natural colors, we do not have the option of plating natural dyes on alumina. For water-soluble natural colors in particular, a natural dye will lead to an undesired outcome.

Why? The answer, of course, is that we will get specking. With water soluble natural colors, there simply isn’t enough water in the application to hydrate the powder, so you get specking. Traditionally, the way to overcome the issue is to increase the usage rate. However, in this instance that is not a great solution because a) this drives up cost-in-use and b) higher usage can raise the issue of off-notes or texture issues.

Use a Plating Grade Natural

Plating grade natural colors that perform like synthetic lakes are a great option for yogurt and compound coating applications. Sensient’s Microfine™ natural color line is a great example. It combines particle size management and encapsulation technology that doesn’t add any incidental (i.e. bad) ingredients and has lake characteristics.

Microfine powder is a good solution and generally works well. In order to ensure homogeneity, a high level of mixing is usually required, but this approach eliminates specking.

Oil based dispersion is what I consider the best solution. A Microfine natural color in an oil-based dispersion actually requires less mixing but results in superior consistency without any specking. I am actually amazed that it is not universally used in compound coatings. A frequent question we get is whether the oil-based dispersions are PHO free, and the answer is yes, as long as the right oil is used.

One Watch out

Naturally oil-based colors such as annatto do not have the same specking challenge as water-based natural colors. However, they are simply not as light stable. In yogurt and compound coatings, my experience has not been as positive with oil-based natural colors as with a plating grade solution.

If you have any questions or projects for which you need guidance on plating grade natural colors, please use this link to set up a consultation or reach out to me directly.