Panning With Natural Colors – Things to Consider

The premiumization trend has the biggest strategic impact on the confectionery market (GlobalData 2019). Consumers are prepared to pay more for higher-quality items options, and brands like YumEarth, Little Secrets, and Unreal are capitalizing on this trend by highlighting ingredients perceived as better-for-you such as natural colors.

As many developers know, formulating with natural colors can pose unique challenges, particularly for panned confectioners. In many cases still today, brands are looking to match a current synthetic FD&C color with a natural alternative. There are a few factors to consider while panning with natural colors, such as pH, heat, moisture, and raw materials.

pH of Coating Syrup

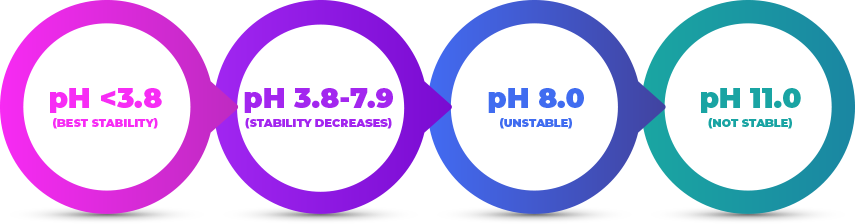

Anthocyanin-based natural colors are largely impacted by pH due to their inherent characteristic to shade shift under pH fluctuations. For example, an anthocyanin can range in shade from a bright pink/red to a green shade simply by modifying the pH. Therefore, if the pH of the coating syrup is not monitored for consistency, you may unfortunately endure shade variation.

However, Sensient’s proprietary pH modification technology enables developers to better control this challenge, especially since small factors like the type of water used in processing can drastically skew your end natural color results. In many cases, tap water is the go-to type in production, leaving little control over mineral presence or acidity which both impact pH. Water quality can vary greatly by region and even change depending on season of the year. Therefore, it is always recommended that a purified water source like distilled, deionized, or RO, but sometimes that’s not an option for manufacturers. It’s astonishing to see how small a pH shift from 4.4 to 4.5 can change a botanical’s performance, but that’s Mother Nature! When we combine science and nature through our patented modification system, no matter the type or pH of your water, your anthocyanin color will exhibit its respective shade with this unique technology.

Heat and Water Activity:

While certainly not an issue for a majority natural colors, certain sources are more susceptible to heat and water content than others. Beet, for example, degrades under high panning temperatures or turns brown due to the heat exposure.

Moisture Content:

Other ingredients in a panned product recipe such as the type of sugar, gums, flavors, or bulking agents, etc. can impact the crystallization of sugar in the panning process. In some cases, these components can also impact the appearance of the color. It all comes down to crystal development. If the added components retain moisture within the shell, it can lead to larger crystal formation. As these large crystals build up throughout the layers of the shell, the end result could have a grainy, opaque appearance. This can make the color seem dull and muted. The converse is possible as well. If some of the components added to the coating syrup are in a liquid form, this will lower the Brix level of the coating syrup and panning conditions will need to be changed to allow for this extra moisture to be removed as each application is dried. If all the moisture is not removed before the polishing step, the residual moisture will accumulate just below the surface of the polishing component and make the color look dull or gray.

Our expert technical team can help determine which colors and ingredients will be problematic in your panning process and offer suggestions to mitigate the issues to keep colors vibrant and appealing.

Manufacturing Environmental Conditions:

Physical processing conditions can also impact end natural color performance but can often be controlled with a mitigation plan in place to keep environmental factors consistent.

Here are the few areas where consistency should be a key target…

- Humidity (i.e. dew point) and room temperature

- Panning Bed: equilibrated mass temperature, bed depth, pan speed, and pan angle

- Undercoat: a “bumpy” undercoat will produce a “mottled” appearance on a finished panned candy product. While many are quick to identify the root cause of this mottled appearance as inconsistent color distribution, the actual culprit is the irregular surface area which in turn causes color to accumulate in those low surface areas. Repeated color coats may seem like a novel fix here, but with additional layering, the low surface areas will just appear darker than the high spots on the surface.

- Drying: If the drying process of each syrup application is inconsistent, “graying” or “dulling” caused by residual moisture can occur, taking you right back to the moisture problems we addressed earlier.

There’s a lot to consider when panning with natural colors, but you are not alone! My team and I are happy to help navigate these complexities to arrive at vivid, naturally colored sugar shelled confections.

We can begin a conversation here if you are ready to get started, just schedule a consultation!