Converting to Natural Colors in Powder Beverage Mixes

Finding the Right Natural Solution

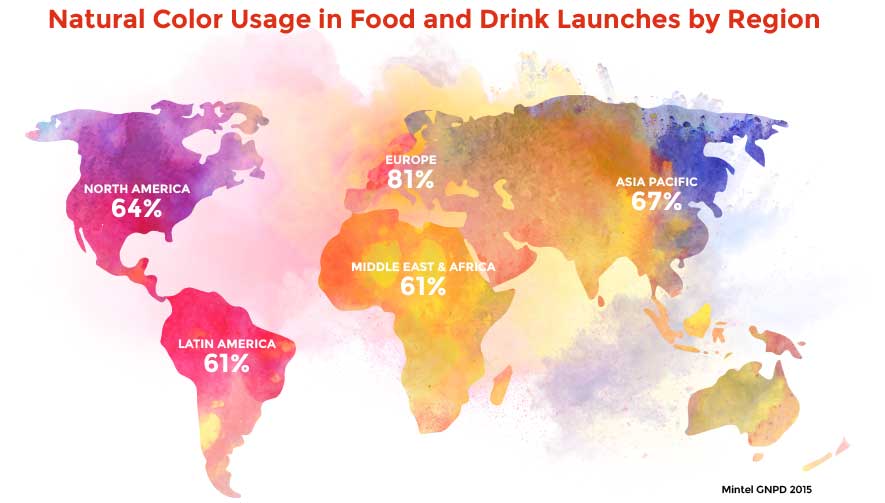

As consumers continue to pledge their allegiance to clean-label trends, packaged food companies are under pressure to replace their artificial colors with those from natural sources. Global new product launch data confirms that brands are recognizing the importance of using simpler and cleaner ingredients, including natural colors.

The powdered beverage category, a staple in many developing markets, has recently shown an increased interest in converting to natural colors. The category is characterized by its intense and vibrant color shades that consumers have come to expect. For product developers, a critical challenge is the higher usage rates required by natural colors to match expected synthetic shades obtained at such low usages. To some, natural color solutions in powder drink mixes can be unchartered territory, especially with sometimes contradictory objectives.

- Desired Shade

- Flavor Expectations

- Solubility and Visibility

- Global Regulatory Compliance

- Cost-in-Use

Desired Shade

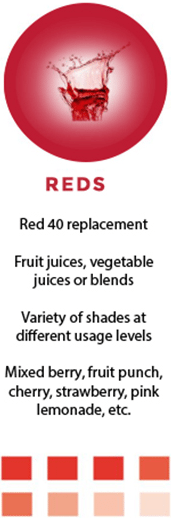

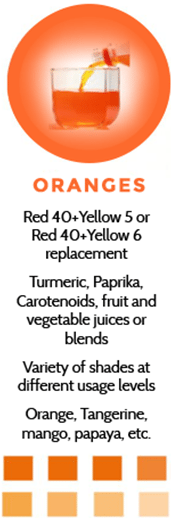

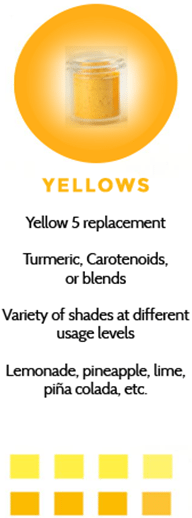

Achieving your desired shade is clearly the main objective in any natural color conversion project. While an exact match to a current synthetic version is usually favorable, cost-in-use or other constraints may facilitate an adjustment to the target shade. For dry powder beverage mixes, the best approach is usually matching the current synthetic shade exactly and then developing potential alternatives that deliver on some of the other objectives. Flexibility is not the same as compromise; it is possible to achieve vibrant, attractive color shades that have strong consumer appeal with natural colors. There are fortunately a variety of natural sources giving us options. Here is a glimpse at some on the market today…

Flavor Expectations

Many natural colors can impart flavor, especially at higher usage rates. Sometimes the flavor can be complimentary to a powdered beverage product and other times unflattering. For example, Carotenoids yield impressive yellow and orange shades similar to FD&C Yellow 5 and 6, but can produce off-flavors. Paprika, from the carotenoid family, carries a spicy off-note into solutions at times. This effect occurs more commonly when these sources are used at higher usage rates to achieve more intense and vibrant target shades in beverages.

Industry advancements in purification techniques help reduce these unwanted flavors while preserving desired shades. One example is Sensient’s Pure-STM technology for natural colors. It provides formulators with cleaner end-solutions, because it gently removes flavor off-notes without resins. Purification innovations such as these in the color world help brands effectively advance in their commitment and progression towards simpler and cleaner labels while delivering the same product taste expected by their consumers.

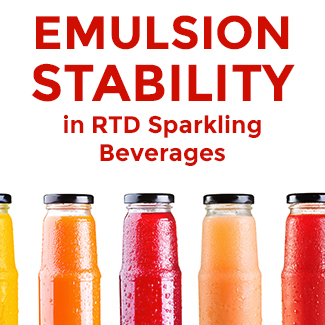

Solubility and Visibility

In many cases, the appearance of the dry powder in beverage drink mixes is critical, because consumers eat and drink first with their eyes. Beverage powders are perceived as more appealing flavors when they are brightly colored in orange, red, or purple, etc. However, standard natural colors do not possess plating characteristics in their powder forms; for example, color from beta carotene would take a long time to dissolve due to its granular powder particles, and the colored powder would end up looking like a salt and pepper mix. A plating-grade natural color that simulates a synthetic lake is an ideal solution for dry drink mixes, like Sensient’s MicrofineTM. Plating characteristics are critical if you want color visible in the powder, they also provide quick solubility after the beverage has been hydrated. If the appearance of color in the powder mix isn’t of concern, a standard natural color powder would be just fine then.

Global Regulatory Compliance

Today, there are more than 100 governmental regulatory bodies, dozens of international trade agreements, and many industrial trade organizations that oversee food regulations. Different risk philosophies are in play depending on the region, and global food manufacturers will need to navigate the diverse regulations on color source compliances that vary by location. It is difficult, if not impossible, to have a single global color solution. R&D teams will probably want to plan for multiple options to address all countries of their powder beverage mix.

Cost-in-Use

As the public’s interest in natural food and beverage ingredients grows, brand marketers are looking to their R&D Directors for colors from botanical sources to keep them relevant to consumers at cost-in-use targets that maintain profitability. There is a direct relationship between color and cost-in-use in powder beverage mixes.

Depending on regional consumer preferences, color visibility may be desired in the dry powder, the finished beverage, or in both. If the powder needs to be naturally colored, then you might need the technology of an excellent plating grade natural solution such as the MicrofineTM where cost-in-use would typically be increased. In contrast, if the color is only required in the finished beverage, a natural color powder would suffice and cost would be standard for that of colors from botanical sources.

Cost-in-use will also vary depending on desired shade intensity, because usage rates will be generally higher for brighter and bolder shades due to natural color’s inherent lower concentrations.

“Naturally replacing artificial colors can be tough, because not all natural colors are created equally, but is possible”

I love to talk color formulation, so if you have a project or just want to talk through some strategies and options, please reach out to me by setting up a consultation.